FTW DR

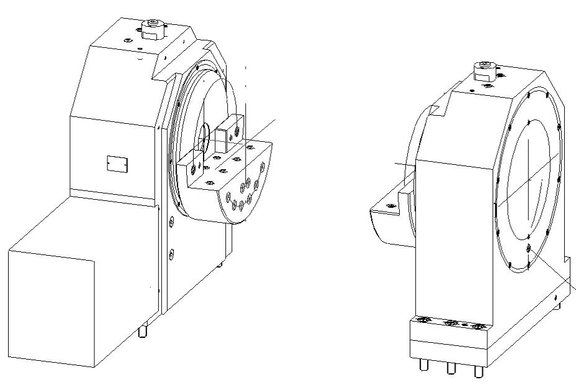

The customized solution with conventional drive

The FTW DR rotary tables with worm drive allow part positioning and simultaneous machining with high torque. They allow an exact positioning even with high machining forces. The tables are equipped with an extremely stable, hydraulic clamping. The drive is equipped with an adjustable worm drive (Ott or Duplex). In special cases we additionally use a planetary gear.

The FTW DR rotary tables can be customized to a large degree and can be supplied in a broad range of variants..

- Horizontal or vertical axis

- Direct or indirect measuring systems

- Standard surface plate (T-notches or bore pattern) or pallet clamping system

- Rotary distributor

Based on FTW DR-modules, tilting rotary tables can be offered in a vast range.

NC Rotary Table with counter bearing - prepared for operation with swivelling bridge.

- Worm gear made of bronze wheel and grinded steel worm shaft

- Hydraulic clamping to take up high machine forces

- Internal rotary coupling

- Encoder based on indexing accuracy request up to ± 1 arc sec.

- Basis face plate with installed connection flange as support for swivelling bridge

- High accurate work piece positioning

- Take up of high machining forces

- Strong housings made of casting materials

- Hydraulic work piece clamping available on request

Technical Data:

|

|

|

320

|

400

|

500

|

630

|

800

|

1000

|

1250

|

1600

|

|

Nominal diameter

|

[mm[

|

320

|

400

|

500

|

630

|

800

|

1.000

|

1.250

|

1.600

|

|

Max. transport load)*

|

[kg]

|

1.000

|

1.600

|

2.500

|

4.000

|

6.000

|

10.000

|

12.000

|

15.000

|

|

Max. moment ofinertia

|

[kgm2]

|

20

|

60

|

150

|

400

|

800

|

2.000

|

4.500

|

8.000

|

|

Max.transport moment

|

[Nm]

|

1.000

|

2.000

|

4.000

|

6.000

|

8.000

|

16.000

|

25.000

|

40.000

|

|

Max.tilting moment

|

[Nm]

|

4.500

|

8.000

|

16.000

|

20.000

|

30.000

|

60.000

|

80.000

|

100.000

|

|

Max.tangential moment

|

[Nm]

|

2.000

|

4.000

|

6.000

|

8.000

|

14.000

|

26.000

|

30.000

|

35.000

|

|

Max. engine speed

|

[rpm]

|

25

|

20

|

20

|

20

|

16

|

12

|

10

|

8

|

|

Usable torque

|

[Nm]

|

1.200

|

2.500

|

3.000

|

4.000

|

7.000

|

14.000

|

16.000

|

20.000

|

|

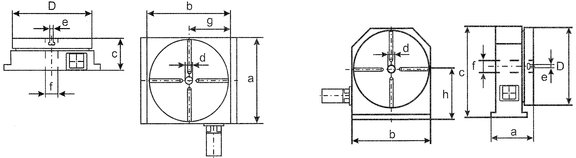

Length a

|

[mm]

|

400

|

450

|

590

|

640

|

800

|

1.000

|

1.200

|

1.450

|

|

Width b

|

[mm]

|

410

|

510

|

570

|

650

|

800

|

1.000

|

1.200

|

1.450

|

|

Height h

|

[mm]

|

220

|

225

|

225

|

255

|

280

|

360

|

420

|

520

|

|

Centering d

|

[mm]

|

28

|

40

|

40

|

40

|

40

|

100

|

100

|

100

|

|

tslot width e

|

[mm]

|

14

|

14

|

14

|

18

|

18

|

18

|

22

|

22

|

|

Net weight

|

[kg]

|

240

|

300

|

450

|

800

|

1.300

|

2.500

|

3.000

|

5.000

|